Advanced Quality Control Systems & Statistical Process Control for Plastic Manufacturing

±0.0001"

MEASUREMENT CAPABILITY

WITH BROWN & SHARPE CMM

100%

INSPECTION PROTOCOLS

FOR CRITICAL DIMENSIONS

ISO 9001:2015

COMPLIANT QUALITY

MANAGEMENT SYSTEMS

Precision Measurement Technology

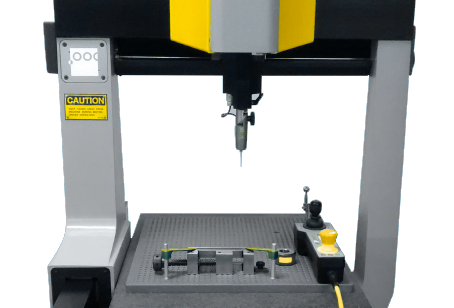

We have access to a Brown and Sharpe PFX 454 MicroExcel Coordinate Measuring Machine (CMM), which when calibrated is capable of dimensional verification with accuracy to ±0.0001 inches. While not currently in active use, this technology can be recommissioned to perform measurements of complex geometries when required. Our quality control approach includes various inspection methods suited to different verification needs, with customized gauging solutions developed for efficient inspection of critical dimensions on plastic components.

Brown & Sharpe CMM

We have a PFX 454 MicroExcel Coordinate Measuring Machine available that, when properly calibrated and commissioned, can deliver dimensional verification with accuracy to ±0.0001 inches. This system can be utilized for verification of complex geometries and critical dimensions when required.

Optical Measurement Equipment

We have an optical comparator available for visual verification of certain part features. While not frequently used, this equipment can be utilized for measuring characteristics that benefit from non-contact methods when needed for specific quality verification requirements.

Customized Gauging Solutions

We develop specialized gauging systems for efficient high-volume inspection, including go/no-go gauges, custom measuring fixtures, and application-specific verification tools tailored to each product's critical dimensions.

ISO 9001:2015 Compliant Quality Systems

Our quality control processes follow ISO 9001:2015 compliant procedures. We maintain consistent, reliable procedures for quality verification throughout production, with documentation of key inspection points. Our quality systems can be tailored to meet specific customer requirements, ensuring that critical dimensions and features are verified to meet exact specifications.

Data-Driven Process Monitoring

We have the capability to implement Statistical Process Control (SPC) methodologies when requested by customers for specific projects. This approach can create a quality system that monitors and improves injection molding processes by gathering data from critical process parameters and part measurements to identify trends and variations. When implemented, this proactive approach helps prevent defects rather than simply detecting them after production.

SPC implementation involves systematic data collection at key control points throughout the manufacturing process. Our team can use measurement equipment to record critical dimensions, surface characteristics, and functional aspects of components. This data can be analyzed using statistical methods that generate control charts and variance reports, enabling process adjustments as needed for critical applications.

While SPC is not a standard part of our regular operations, we maintain the knowledge and ability to implement these protocols when required for specific customer needs. This approach can help achieve consistency across production runs, reduce scrap rates, and improve overall efficiency while maintaining appropriate quality standards for your specific requirements.

Benefits of Statistical Process Control

- Early detection of process drift before quality issues occur

- Significant reduction in process variation and defects

- Data-driven insights for continuous improvement

- Consistent part quality across production runs

- Lower scrap rates and improved efficiency

- Comprehensive documentation for traceability

- Reduced inspection time with targeted sampling

- Objective quality validation with statistical confidence

Available SPC Implementation Elements

- Control charts for critical dimensions

- Process capability analysis (Cpk)

- Trend and pattern identification

- Root cause analysis

- Measurement system analysis

- Statistical sampling plans

- Preventive action protocols

- Process validation documentation

Quality Assurance Process

Comprehensive Quality Control Throughout Production

Our quality assurance process begins with incoming material verification, where we confirm that all raw materials meet specifications before entering production. This includes material certification validation, physical property testing, and moisture content verification to ensure optimal molding conditions.

For each new production run, we conduct appropriate first article inspections that verify critical dimensions, functional characteristics, and appearance requirements. This establishes baseline quality metrics that guide subsequent in-process checks performed at strategic intervals throughout the production cycle. Our in-process quality checks include monitoring of important process parameters and measurement of key component dimensions.

Final inspection protocols include dimensional verification using appropriate measuring equipment, visual inspection for surface defects, and functional testing as applicable. Every step of our quality process is documented with inspection reports, material certifications, and quality data as needed. Our ISO 9001:2015 compliant quality system helps us maintain traceability from raw material to finished product, ensuring consistency across production runs.

Frequently Asked Questions About Quality Control & SPC

Get answers to common questions about our quality control and statistical process control capabilities. If you need additional information, our quality team is ready to assist with your specific requirements.

What is Statistical Process Control and how does it improve quality?

Statistical Process Control (SPC) is a data-driven methodology that monitors manufacturing processes to detect and prevent quality issues before they occur. By collecting and analyzing data from key process variables and product measurements, SPC identifies trends, variations, and potential problems that could affect quality. This proactive approach enables adjustments to maintain processes within optimal parameters, resulting in fewer defects, more consistent products, and continuous quality improvement. We can implement SPC methodologies upon customer request for specific projects that require this level of process control.

How accurate is Norco's measurement equipment?

We have various measurement tools available to meet different inspection needs. Our standard measuring equipment includes precision calipers, micrometers, and custom gauging solutions that provide accurate dimensional verification for most applications. We also have a Brown and Sharpe PFX 454 MicroExcel Coordinate Measuring Machine (CMM) that, when calibrated, can provide measurement accuracy to ±0.0001 inches (2.54 microns). While the CMM is not in regular use, it can be recommissioned for specialized measurement needs. We select appropriate measurement methods based on part requirements and critical dimensions to ensure quality standards are consistently met.

What quality certifications does Norco maintain?

Norco Plastics maintains a quality management system that aligns with ISO 9001:2015 principles and practices. While we are not ISO certified, our quality system is compliant with ISO 9001:2015 standards, incorporating specific protocols that meet industry requirements for various applications including automotive, consumer products, and construction. We tailor our quality processes to each industry's specific needs, ensuring consistent quality regardless of application. Our quality team regularly reviews and updates our systems to incorporate best practices and respond to evolving industry requirements.

How does Norco handle quality issues if they arise?

If a quality issue is identified, we implement a structured problem-solving approach that begins with immediate containment to prevent any non-conforming products from reaching customers. Our quality team conducts thorough root cause analysis to identify the source of the issue. We then develop and implement corrective actions, validate their effectiveness, and establish preventive measures to ensure the issue doesn't recur. Throughout this process, we maintain transparent communication with customers, documenting findings, actions, and verification results to ensure complete resolution. This systematic approach helps us address quality concerns efficiently and effectively.

What documentation is provided with quality inspections?

Our quality documentation includes inspection reports that verify critical dimensions and characteristics against specifications. Depending on project requirements, documentation may include first article inspection reports, material certifications, and in-process inspection data. For projects with specific quality requirements, we can provide additional documentation such as SPC charts when requested. Our documentation system allows us to maintain records of quality data and provide this information to customers as needed to support their requirements or compliance needs. We tailor our documentation approach to match the specific quality requirements of each project.

Need more information about our quality control capabilities?

Contact Our Quality TeamNeed Quality Control for Complex Plastic Components?

Contact us about your quality requirements. Our quality management system follows ISO 9001:2015 compliant processes to ensure consistent and reliable verification for your plastic components. We offer customized inspection approaches based on part complexity and critical dimensions, with the ability to implement statistical process control when required for specific applications. Our quality team works closely with you to ensure your parts meet all necessary specifications and standards.