Advanced Plastic Injection Molding Equipment & Machinery with 30-2800 Ton Capacity

30 - 220 TON Manufacturing Systems

- All systems come equipped with a Cartesian robot and Maguire mixing system

- Hydraulic components designed for precision control and low pressure processing capabilities

- Perfect for applications requiring high repeatability and tight tolerances

- Energy-efficient drive system with electric motors reduces operating costs

- Quick changeover capabilities with optimized barrel and screw design for flexible production

390 - 610 TON Processing Equipment

- All systems feature Cartesian robots and Maguire mixing systems

- Electric motor driven injection units with precision screw control

- Advanced barrel heating systems for optimal plasticizing efficiency

- State-of-the-art control system with comprehensive nozzle and mold temperature regulation

- Energy-efficient hybrid drive systems reduce operational costs and improve throughput

720 - 1100 TON Manufacturing Systems

- All systems come equipped with Cartesian robots and Maguire mixing systems

- High precision injection control systems with multi-stage pressure profiles

- Advanced direct drive technology for energy efficiency and performance

- Sophisticated clamping unit design with optimized tie-bar spacing for larger molds

- State-of-the-art controls for complex process monitoring and tonnage adjustment

1430 - 1800 TON Processing Equipment

- Advanced servo-hydraulic systems with direct drive technology for superior energy efficiency

- Engineered for maximum stability during high-pressure injection with specialized barrel and screw configurations

- Precise temperature control across multiple zones with advanced nozzle designs

- Electric motors with optimized control systems to reduce energy consumption while maintaining high throughput

- Ideal for automotive, large appliance, and industrial container applications requiring substantial mold clamping force

2800 TON Manufacturing Capability

- Our most powerful system with 2800 ton of mold clamping force for large-scale production

- Advanced injection unit with specialized barrel and screw design for optimal plasticizing

- Features Maguire mixer/feeder system with precision material handling and control

- Independent motion technology with direct drive system for maximum precision and optimized processing

- Ideal for extremely large parts and high-volume production with exceptional control capabilities and industry-leading tonnage

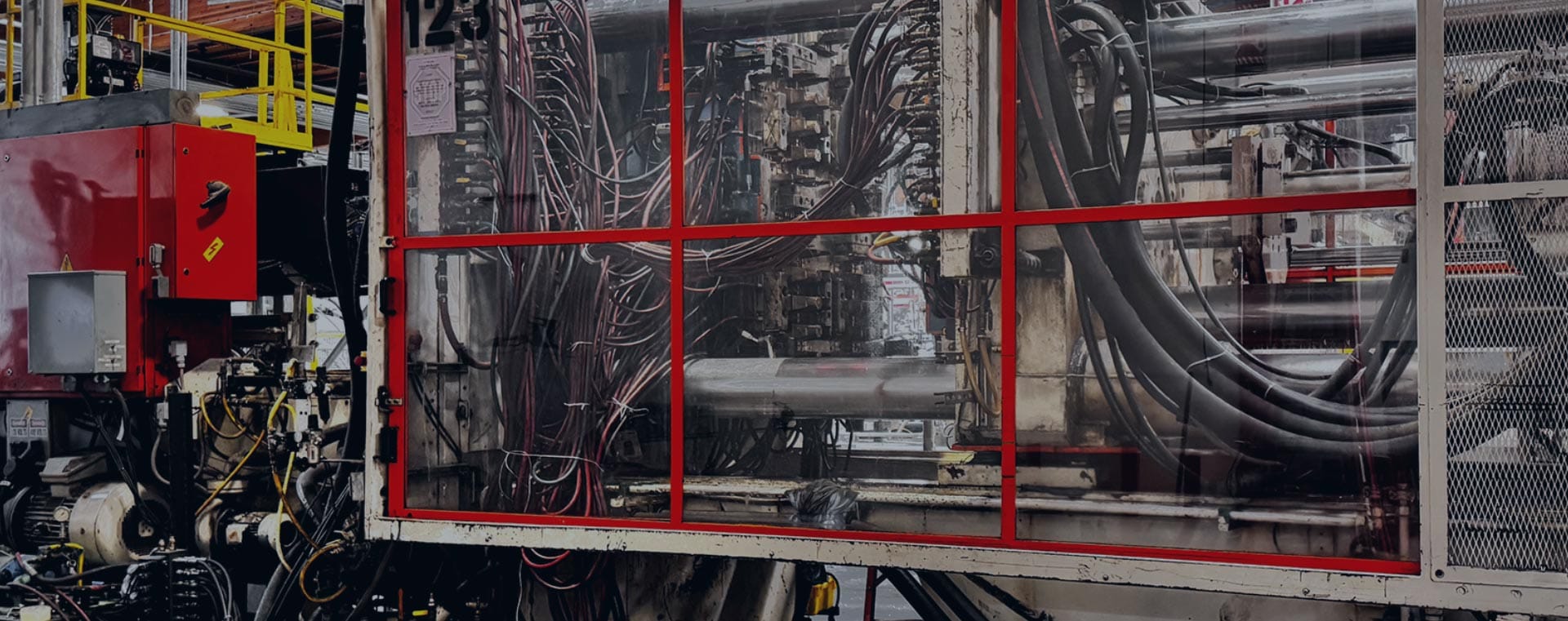

PLASTIC INJECTION MOLDING MACHINERY

High-Capacity Equipment in Action

Complete Plastic Injection Molding Solutions

Our comprehensive range of plastic injection molding equipment offers versatility and high precision for a variety of projects. From specialized components to large-scale production, our molding machines deliver consistent quality products with exceptional throughput and efficiency.

Versatile Injection Units

Our plastic injection manufacturing systems feature specialized barrel designs and precision screw configurations for optimal plasticizing. These units deliver consistent material flow and temperature distribution, ensuring superior part quality while minimizing material waste through efficient processing.

Precise Mold Clamping Systems

From 30 to 2800 tons, our injection molding machines provide exceptional mold clamping force control using sophisticated hydraulic systems. The direct drive technology ensures precise pressure distribution and stability throughout the production cycle, preventing defects and ensuring dimensional accuracy for molded plastic components.

Advanced Control Systems

Our plastic injection molding equipment incorporates sophisticated control systems that monitor and adjust process parameters in real-time. These electric motor-driven controls optimize material usage, reduce waste, and ensure consistent part quality with minimal operator intervention while maintaining detailed production records for quality assurance.

Production Efficiency

Our injection molding machines feature innovative technologies that maximize throughput without compromising quality. Advanced cooling systems, efficient material heating, and rapid mold movements work together to reduce cycle times while maintaining precise control over every phase of the production cycle for custom plastic injection applications.

Technical Documentation

Each plastic injection molding machine in our facility is supported by comprehensive technical documentation including tonnage specifications, maintenance schedules, and process equipment guidelines. This documentation ensures consistent operation and simplifies process validation and quality audits for both standard and custom plastic injection molding projects.

Automation Integration

Our injection molding machinery integrates seamlessly with robotic automation for part removal, material handling, and secondary operations. These automation solutions enhance productivity, ensure consistent part handling, and enable continuous operation for high-volume production requirements while reducing labor costs. We offer a range of process equipment options to meet your specific manufacturing needs.

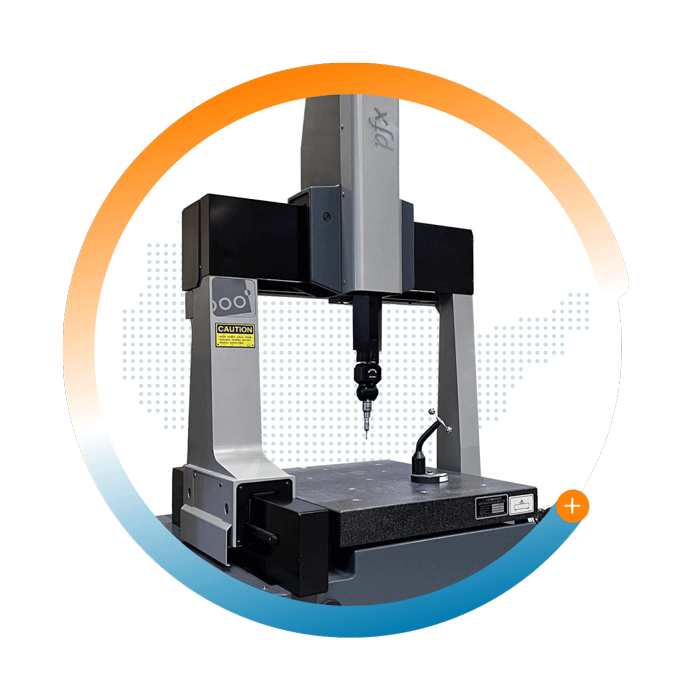

Advanced Measurement for Injection Molding Excellence

Our equipment is complemented by state-of-the-art quality control technology. We've implemented the Brown and Sharpe PFX 454 MicroExcel CMM (Coordinate Measuring Machine), ensuring dimensional accuracy to ±0.0001 inches across a range of operating parameters. This advanced system enables comprehensive Statistical Process Control (SPC) monitoring for consistent quality throughout the injection molding process. The integration with our molding machines allows for efficient cycle times while maintaining high precision specifications. Our mold clamping systems ensure that every plastic injection component meets exact dimensional requirements, regardless of complexity. The combination of direct drive systems, electric motors, and automated validation creates a manufacturing environment where injection molding machinery performs at peak efficiency, delivering exceptional quality with every production run.

Common Questions About Plastic Injection Molding Equipment

What is an injection molding machine and how does it work?

An injection molding machine is specialized manufacturing equipment used to produce plastic parts by injecting molten material into a mold. The equipment consists of two main parts: the injection unit and the clamping unit. The injection unit melts plastic pellets in the barrel using heat and the rotating action of the screw, then injects this molten material into the mold cavity. The clamping unit secures the mold closed against the injection pressure using carefully calculated mold clamping force, measured in tons. Our facility houses various types of plastic injection molding machines, including hydraulic systems, electric motor-driven units, and hybrid designs, with clamping capacity ranging from 30 to 2800 tons. Modern injection molding machinery incorporates direct drive system technology for energy efficiency and precise control over processing parameters, barrel temperature, and material flow.

How do you determine what size injection molding machine is needed for a project?

Determining the appropriate molding machine size involves evaluating several key factors for plastic manufacturing. The primary considerations include the shot size (volume of material required), the projected area of the part multiplied by the material's specific pressure requirements, and the physical dimensions of the mold. The necessary mold clamping force is calculated using the projected area of the part and the specific pressure requirements of the material being processed. Generally, a safety factor of 4-5 tons per square inch of projected area is used. Additionally, the mold dimensions must fit within the tie-bar spacing of the processing equipment, with sufficient clearance for operation. Our range of injection molding machines from 30 to 2800 tons allows us to accommodate parts from small precision components to large industrial products. Our engineering team carefully evaluates each project to determine the optimal machine selection, injection unit capacity, and required clamping specifications.

How does back pressure work in injection molding machines?

Back pressure is a critical setting in plastic processing that significantly affects material quality during manufacturing. It refers to the resistance applied against the screw during the plasticizing phase when the screw rotates and retracts to prepare material for the next shot. Our plastic injection molding equipment allows precise control of back pressure to optimize material processing. Higher back pressure increases the mechanical work done on the material, improving homogenization of the melt, dispersing additives more effectively, and releasing trapped air. However, excessive back pressure can lead to material degradation, extended cycle times, and increased wear on the injection unit. Our molding machines feature advanced control systems that allow operators to precisely set and monitor back pressure according to specific material requirements, helping to achieve optimal material quality while maintaining efficient production and protecting the integrity of temperature-sensitive materials.

What is the difference between high and low pressure in injection molding?

In manufacturing, pressure control is essential for producing high precision parts, and our injection molding machines offer precise control over various pressure settings throughout the production process. High pressure typically refers to injection pressures of 15,000-30,000 PSI at the nozzle. This high pressure is used during the filling phase to rapidly move material into the mold cavity, ensuring complete filling of complex geometries and thin-walled sections. In contrast, low pressure molding operates at significantly reduced levels, typically 2,000-8,000 PSI. These moderate pressure techniques are used during the packing and holding phases to gently fill remaining voids and compensate for material shrinkage without inducing high levels of stress in the part. Our plastic injection molding equipment includes advanced control systems that allow for precise pressure profiling throughout the cycle. This capability enables our machinery to produce parts with minimal internal stress, reduced warpage, and excellent dimensional stability. The ability to transition between pressure levels during different phases is a key feature of our modern manufacturing equipment.

How do you prevent or fix parts breaking in an injection molding machine?

Preventing parts from breaking during the manufacturing process involves careful control of process parameters and proper equipment selection. Our approach combines advanced plastic injection molding machines with systematic optimization to maximize throughput while achieving high precision results. First, we ensure proper mold design with adequate draft angles, appropriate gate locations, and optimized cooling systems. We carefully match the equipment's mold clamping force and injection unit capacity to the part requirements. During setup, we optimize processing parameters including barrel and mold temperatures, injection speeds, holding pressure and timing, cooling periods, and mold opening/ejection speeds. Our injection molding machines feature sophisticated control systems that maintain consistent cycle times and repeatability. If part breakage occurs despite these preventive measures, we conduct a systematic investigation, analyzing the part and processing parameters. Common solutions include adjusting mold temperatures, modifying cooling times to ensure proper solidification, optimizing ejection mechanisms, refining gate design, or examining material selection. Our diverse range of plastic injection molding machines allows us to transfer problematic parts to machinery with different specifications if needed.

Need Precision Plastic Manufacturing in Los Angeles, Riverside, San Diego & Orange County?

Looking for quality injection molding near me? Contact us about your next plastic manufacturing project. Our team specializes in custom plastic injection molding with large tonnage equipment up to 2800 ton and 24/7 production capabilities. We deliver high quality products backed by over 50 years of experience and comprehensive quality management systems. Let us put our expertise to work for your business needs.