Custom Plastic Mold Injection Services in California

Southern California's Premier Injection Molding Company | Large Tonnage Specialists Since 1974

88,000 sq. ft.

PLASTIC MOLD INJECTION FACILITY

LOCATED IN CHINO, CA

25 Presses

CUSTOM PLASTIC INJECTION MOLDING

30 ton - 2800 ton

24/7

SOUTHERN CALIFORNIA INJECTION MOLDING

SERVING RIVERSIDE, ORANGE & LA

ABOUT NORCO PLASTICS

HIGH QUALITY PLASTIC INJECTION MOLDING SINCE 1974

Founded in 1974 by the Williams family in Norco, California, our company has grown from a small operation with just two machines to become one of Southern California’s leading injection molding companies. Today, the second generation of the Williams family continues this legacy of excellence from our 88,000 sq. ft. Chino facility, serving businesses throughout Los Angeles, Riverside, Orange County, San Bernardino, and San Diego with custom plastic injection molding solutions.

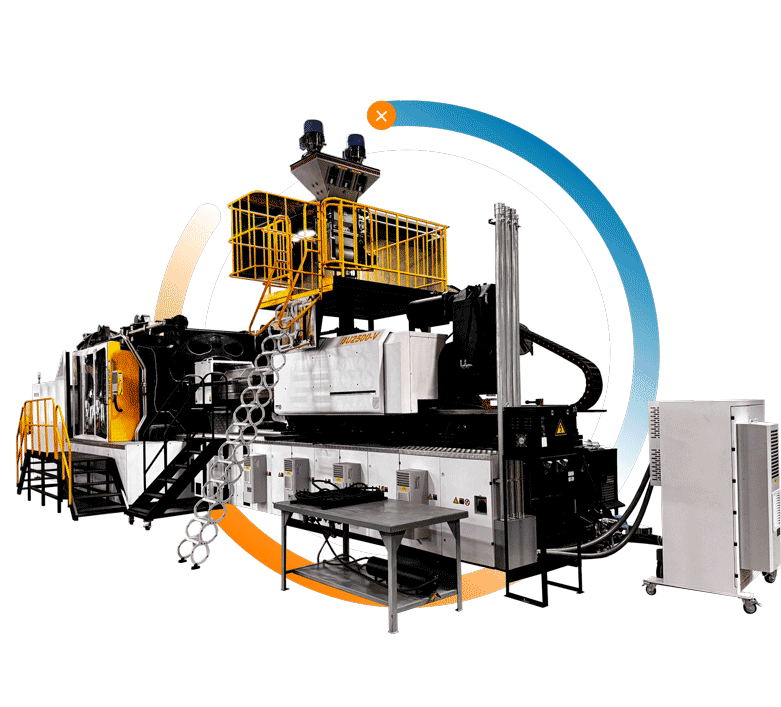

Over five decades, we've continually invested in edge technology, expanding from small-scale production to include plastic molding with large tonnage capacity up to 2800 ton—a milestone achieved in 2023 with our newest press installation. This commitment to growth, combined with our 24/7 operation and over 50 years of molding experience as a trusted production partner, allows us to deliver high quality products and precision that other molding company operations simply cannot match.

Plastic Mold Injection Machinery

As leading injection molding companies California businesses rely on, our facility houses 25 precision molded plastic manufacturing machines ranging from 30 to 2800 ton of clamping force, with shot capacity up to 1000 oz. Our plastic molding equipment enables us to provide high quality plastic injection solutions with 24/7 production capabilities.

Whether you need custom plastic injection molding for small precision components or large-scale parts, our services deliver consistent quality products that plastic manufacturers in California rely on. Our edge technology and experienced team ensure superior results for a wide range of plastic molding applications of any size.

Custom Plastic Injection Molding Solutions

Custom Plastic Injection Molding Solutions

High Quality Precision Plastic Manufacturing

Our California facility delivers injection molded components for a variety of industries throughout Los Angeles, Riverside, San Diego, and Orange County. With over 50 years of molding experience in plastic injection, we provide a complete range of custom plastic solutions for projects of all sizes using edge technology and process equipment.

Automotive

Automotive Medical

Medical

Construction & Infrastructure

Our Southern California injection molding company specializes in high quality products for the construction industry including weather-resistant barriers, specialized fittings, and molded plastic structural supports engineered to withstand extreme conditions.

- Weather-resistant components for outdoor applications

- Pond supply systems and water management solutions

- Structural supports with superior load-bearing capacity

- Custom plastic injection molding solutions for California building codes

Storage & Logistics Solutions

Our facility manufactures high-impact storage totes, bins, and customized container systems engineered for modern logistics and supply chain operations. Our comprehensive range of injection molded products feature reinforced corners and stackable designs that optimize warehouse space.

- Reinforced corners for maximum durability in warehouse environments

- Stackable designs to optimize storage space efficiency

- High-impact resistance for demanding logistics applications

- Exact dimensions for automated handling systems

Housewares & Consumer Products

Our California plastic manufacturing facility creates food-grade housewares, baby products, and pet supplies manufactured with BPA-free materials through precision plastic injection molding processes optimized for consumer goods.

- BPA-free materials for food contact applications

- Premium color matching for brand consistency

- Heat-resistant and dishwasher-safe components

- Ergonomic designs for consumer satisfaction

Irrigation & Agricultural Components

Our agricultural solutions feature UV-stabilized materials designed specifically for California's farming conditions, delivering irrigation components that withstand harsh outdoor environments while maximizing water efficiency.

- UV-stabilized materials for outdoor agricultural applications

- Water-efficient irrigation designs for sustainable farming

- Temperature-resistant components for extreme weather

- Custom solutions for California agriculture industry needs

Automotive Components

We manufacture high-performance automotive parts using custom plastic injection techniques that meet the rigorous standards demanded by today's vehicle manufacturers and aftermarket suppliers.

- Tight tolerances for precise automotive component fitting

- Heat-resistant materials for under-hood applications

- Complex geometries for modern vehicle designs

- Quality control systems meeting automotive industry standards

Non-Invasive Medical Components

We manufacture high-quality non-invasive components such as storage trays, transport containers, and external device housings for the healthcare industry, delivering precision and reliability for medical applications.

- Medical-grade materials for healthcare applications

- Precision manufacturing for consistent quality

- Cleanroom production capabilities when required

- Regulatory compliance for healthcare standards

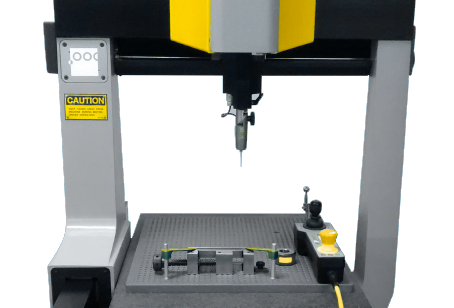

Quality Control for Custom Injection Molding

Precision Measurement for Plastic Manufacturing

Our Chino facility features advanced quality control technology including the Brown and Sharpe CMM for precise dimensional verification of molded plastic components. We implement Statistical Process Control (SPC) monitoring throughout our plastic molding production to ensure consistent results that meet high quality standards. From incoming materials to final inspection, our quality system verifies every molded plastic component meets exact specifications, delivering superior custom plastic injection molding products. With over 50 years of experience in plastic molding as plastic injection molding company experts in California, we provide an extensive range of services with exceptional customer service for all your injection molded projects throughout Southern California.

Learn About Our Quality Process

Need Precision Plastic Manufacturing in Los Angeles, Riverside, San Diego & Orange County?

Looking for quality injection molding near me? Contact us about your next plastic manufacturing project. Our team specializes in custom plastic injection molding with large tonnage equipment up to 2800 ton and 24/7 production capabilities. We deliver high quality products backed by over 50 years of experience and comprehensive quality management systems. Let us put our expertise to work for your business needs.